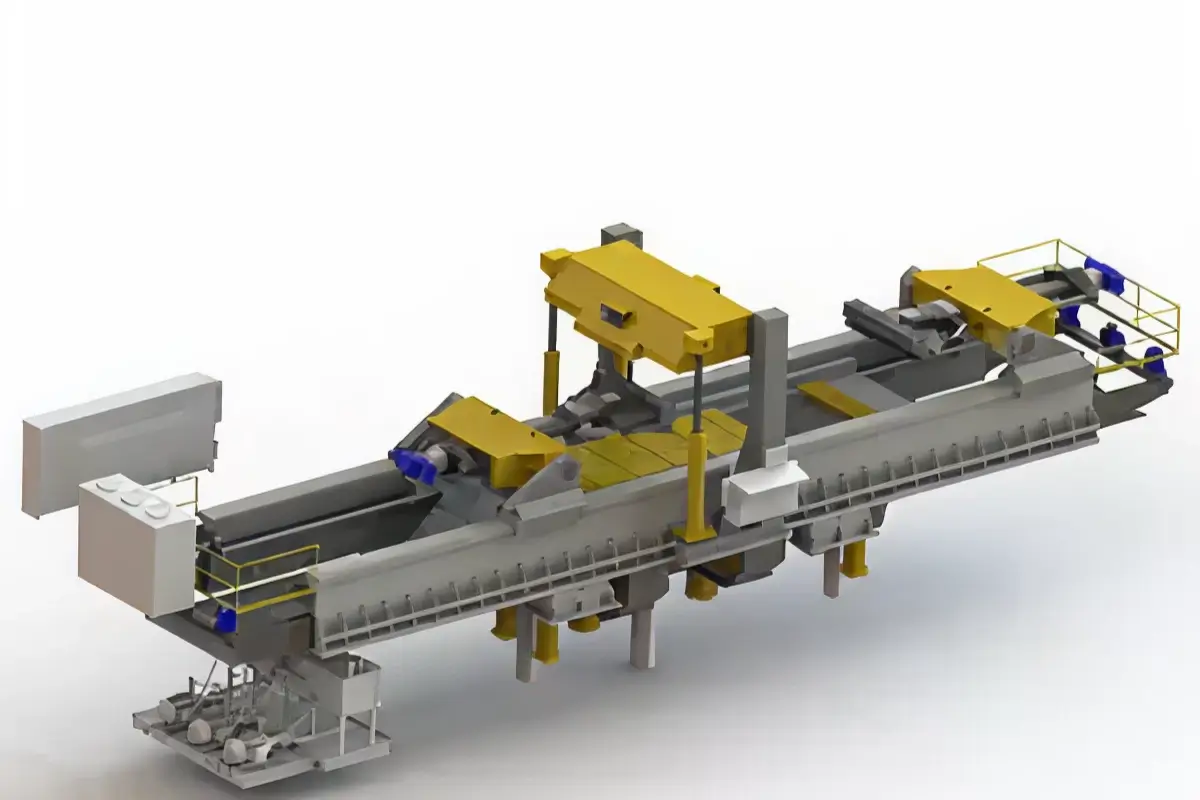

A stretch forming machine takes flat metal and transforms it into sleek, contoured shapes with flawless accuracy. Combining controlled tension with a form die creates complex curves that look seamless and perform reliably in real-world conditions.

From aerospace panels to architectural components, our stretch forming machines allow us to form large parts with the precision that manual methods cannot match.

Shaping Complex Curves with Precision and Consistency

Stretch forming machines reshape metal by pulling it under tension and pressing it against a die that matches the desired curve. This controlled process keeps the material smooth and uniform, eliminating wrinkles and weak points that can appear with other forming methods.

The end result is a part with precise geometry across its entire surface, even when produced in large sizes.

With the right stretch forming machine, manufacturers achieve consistency part after part, all while keeping waste to a minimum.

Industries and Parts That Rely on Stretch Forming Machines

Stretch forming machines serve industries where smooth contours and exact tolerances are critical to performance and appearance. They allow the production of large, complex pieces that would be difficult or inefficient with other methods.

These industries include:

- Aerospace: Fuselage skins, wing panels, window frames, and structural supports

- Transportation: Train panels, automotive trim, and body components

- Architecture: Curved façade panels, roofing elements, and decorative structures

- Marine: Hull sections and superstructure components shaped for strength and flow

- Energy: Turbine housings and large casings requiring aerodynamic profiles

Each sector depends on stretch forming machines to create parts that combine strength, visual quality, and dimensional precision.

Technology That Defines a Modern Stretch Forming Machine

Today’s stretch forming machines combine hydraulic power with precision controls to deliver uniform tension across every part of the workpiece.

Adjustable jaws secure the material at both ends, while programmable settings allow operators to fine-tune pressure and bending speed for different alloys.

Advanced machines integrate CNC technology to replicate exact curves on every cycle, even for large aerospace skins or architectural panels. This blend of strength and automation is what separates modern stretch forming from older, less consistent methods.

Advantages of Working With Experienced Stretch Forming Machine Manufacturers

Partnering with established stretch forming machine manufacturers ensures access to proven designs that have already performed in demanding industries. Our decades of engineering knowledge translate into equipment that balances tonnage, jaw capacity, and control systems with real production needs.

Buyers also benefit from long-term support programs, a huge machine parts library, and services that keep machines at peak performance.

With all of these benefits, you get total confidence that every order will ship on time and meet your exact specifications.

Custom Engineering Options for Specialized Forming Requirements

Not every operation forms the same material, shape, or panel size, which is why custom stretch forming machines are often the best fit.

We design equipment with variable jaw spacing, die bed dimensions, and control packages to match each facility’s production flow. Some clients require extended stroke lengths for oversized aerospace skins, while others need tighter control for thin automotive trim.

Our tailored engineering ensures the machine works for your parts – not the other way around.

Stretch Forming Machine FAQs

Find out more about our stretch forming machines through these FAQs.

How large a part can a stretch forming machine handle?

Capacity depends on the jaw opening, stroke length, and overall design of the stretch forming machine. These machines can produce large aerospace panels, train sidewalls, and long architectural components.

What materials can a stretch forming machine shape?

Stretch forming machines can form aluminum, steel, titanium, and other alloys without cracking or thinning. The process applies even tension so metals bend smoothly over the die, making it ideal for aerospace-grade aluminum panels and architectural cladding.

Do stretch forming machines improve surface quality?

Yes, the process creates smooth, wrinkle-free surfaces that often reduce or eliminate the need for secondary finishing.

What kind of maintenance does a stretch forming machine require?

Regular checks on hydraulic systems, jaw alignment, and control calibration keep the machine performing consistently.

Talk to Our Stretch Forming Experts Today

Ajax/CECO/Erie Press only offers the best, most reliable stretch forming machines. Our team works directly with aerospace, transportation, and architecture manufacturers to configure equipment that matches exact production requirements.

Reach out today to start planning a stretch forming machine that keeps your operation ahead of schedule and ahead of the competition.