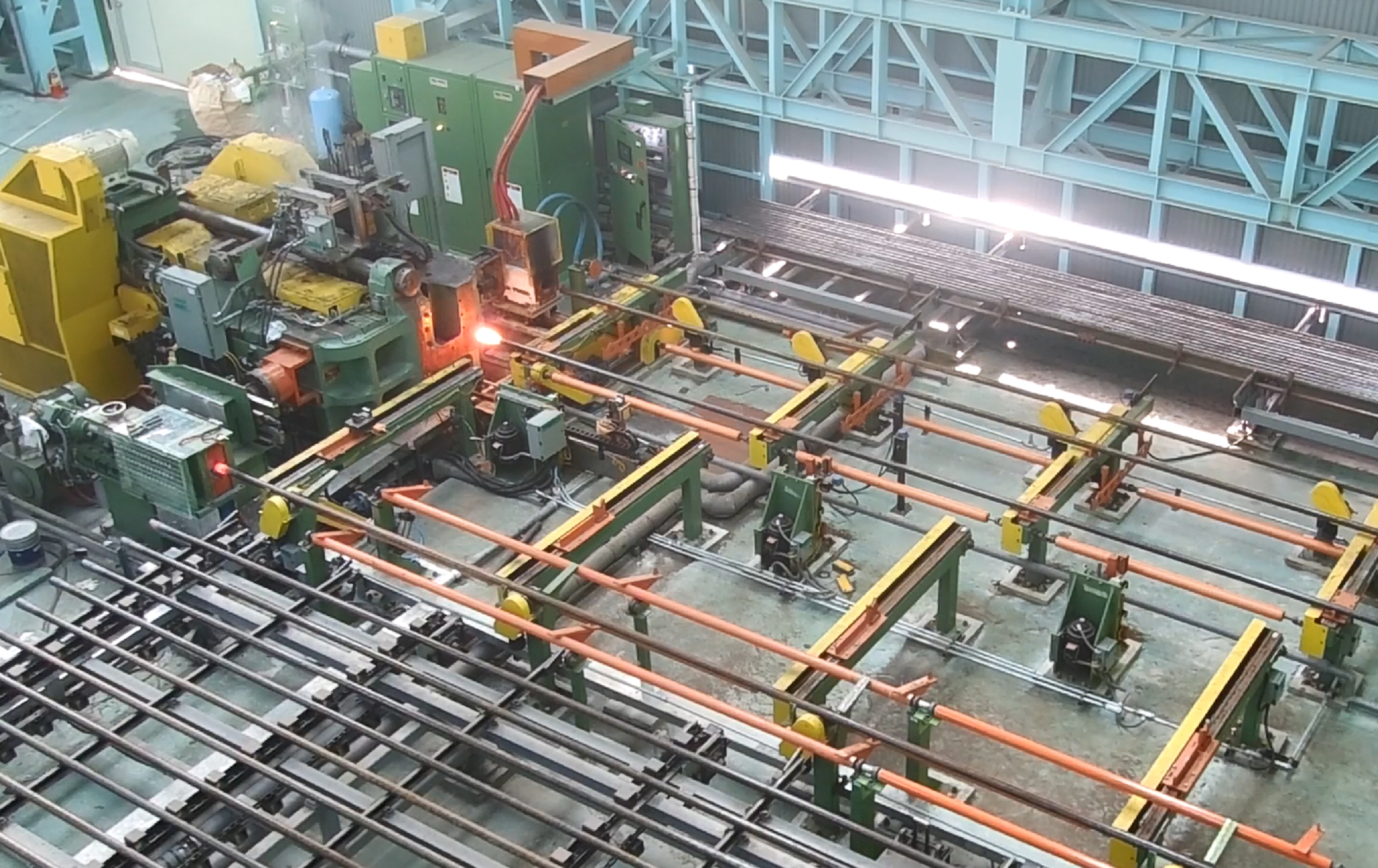

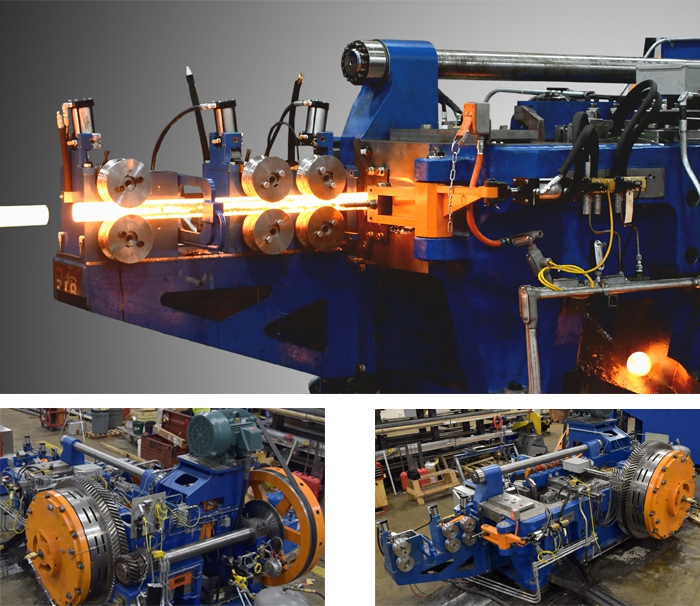

From upsetter/forging machines and tube upsetters to solid-die ball forging machines, we engineer robust and efficient solutions tailored to the demanding needs of your industry. Known for our innovative designs, precision shearing and forging, and the capability to handle high loads, we’re trusted by industries worldwide.

Whether you’re in the oil and gas sector, need equipment for the mining industry, or are seeking advanced automation in high-production forging, we have you covered. Experience the blend of reliability, productivity, and industry-focused solutions with our state-of-the-art machinery.