START YOUR PARTS STOCKING PROGRAM TODAY

Unplanned machine downtime is a productivity killer.

That’s why Ajax/CECO/Erie Press is dedicated to keeping you forging—no matter what.

With our Parts Stocking Program, we will design a comprehensive inventory plan specific to your industrial forging requirements, reducing downtime in manufacturing.

Enroll in our program today!

PARTS STOCKING PROCESS

We make the process simple so you can focus on productivity and not worry about lead times, missing parts, or manpower to ensure you have the parts inventory necessary to decrease unplanned machine downtime.

- Our experienced technicians will review your unique forging equipment needs.

- They will then make recommendations for the optimal parts to add to your program. Recommendations will also include the consumables you should always have in stock for your manufacturing process.

- Ajax/CECO/ Erie Press will inventory your parts at our manufacturing and service locations until you need them.

By being prepared in this way, you’re always ready to get back up and running faster when downtime occurs.

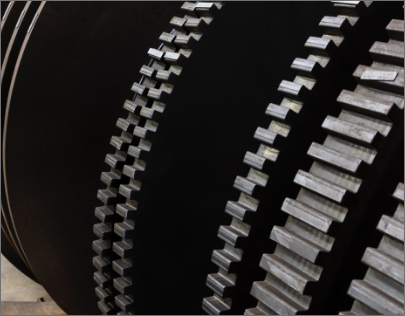

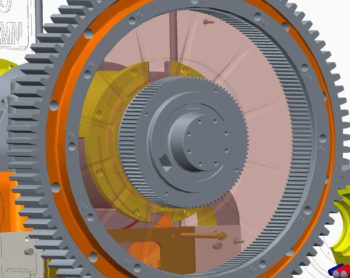

This program will limit exposure to avoidable disruptions that result in extended and costly downtime for your forging operations. Forging companies with our Forging Presses, Forging Rolls, Programmable Hammers, Upsetters and Wire and Bar Drawers find value in our custom designed stocking program which offers our them a specifically detailed program that will promote the longevity of their forging equipment.

Forging applications have complex parts that often have long lead times. By stocking frequently ordered parts and parts with Ajax/CECO/ Erie Press you will be able to diminish the long lead times and increase your equipment’s uptime.

To discuss how we can help boost your uptime contact us today!

Our techs will determine the necessary parts for your equipment based on supply chain and burn rate to reduce downtime and provide quick turnaround for maintenance and repairs of your equipment.

The stocking program will help you reduce upfront costs for parts and bill you in installments rather than require payment in full when the order is placed.

At Ajax/CECO/ Erie Press we manufacture parts for nearly all of our OEM machines, we can help your ROI by manufacturing your parts in a semi-finished state to make them interchangeable for different machines and complete the fabrication when you need them.

- Shorter lead times. By stocking frequently ordered parts and parts you can’t afford NOT to have on hand, you dramatically shorten lead times and decrease downtime.

- Flexibility. To help save you time and reduce your costs, we often manufacture parts for the Stocking Program to a semi-finished state—so they may be interchangeable for several machines depending on the machine design—and then finish them to precise specifications when you call.

- Minimal upfront costs. Rather than paying for the expensive parts after shipment or upfront when they are ordered, we only require a percentage of the cost at order placement. We will charge in installments against the balance of the part, and the balance will not be due until you request a part to be shipped. We will store them for up to two years for you with no other payments to be made.

In addition to the Parts Stocking Program, Ajax/CECO/Erie Press is now offering the most comprehensive preventative maintenance program in the forming and forging industry. The program aims to be an extension to your maintenance team — to support your maintenance operation in the development and execution of their maintenance strategy to unexpected eliminate equipment failure.

Increase your productivity with our stocking program and preventative maintenance program, contact us today to find out how.

Preventative Maintenance Program

At Ajax/CECO/Erie Press, we don’t just build machines; we build relationships.

For more information about our stocking program and other types of forging methods, we support contact us!