Ajax/CECO/Erie Press engineers forging automation systems that match the demands of modern metal forming. With expertise in robotic forging and control integration, we help manufacturers upgrade legacy operations and bring greater control to every stage of the forging process. Scroll below to explore our precision forge automation options.

Advanced Forge Automation Systems for Industrial Workflows

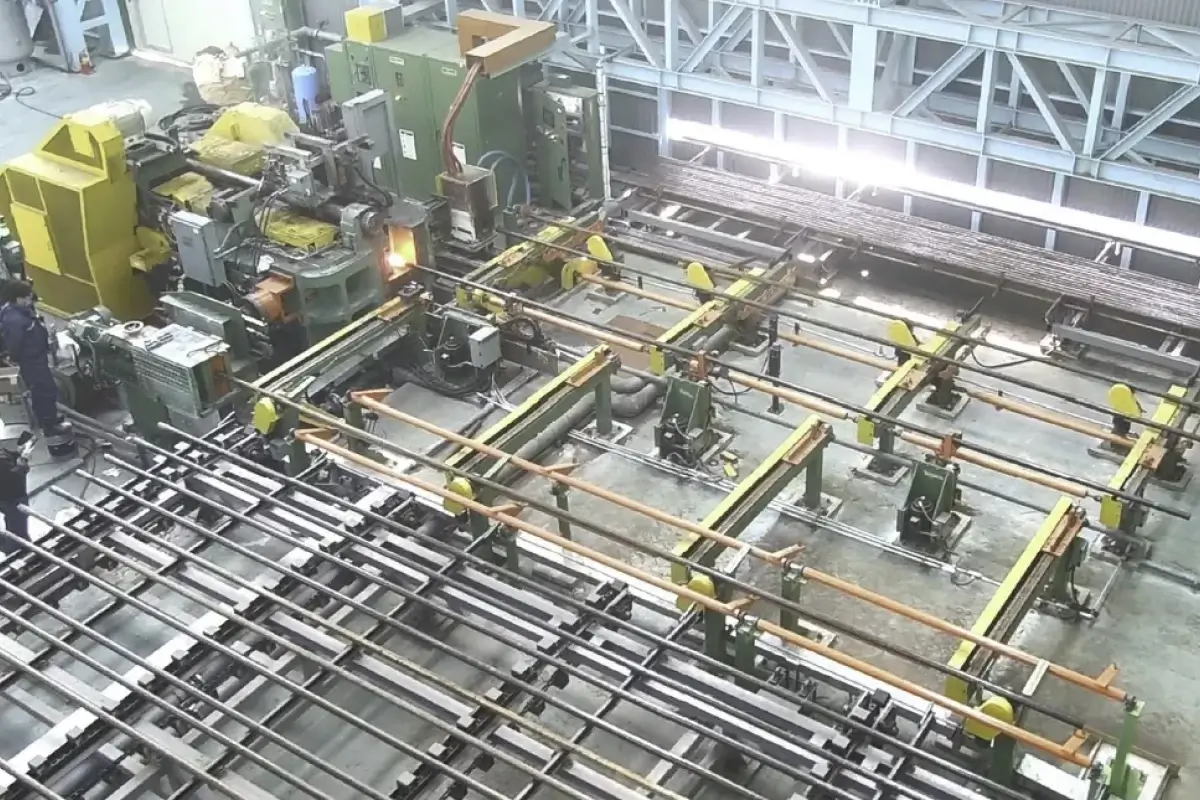

The experts behind Ajax/CECO/Erie Press build forging automation systems that manage the movement of billets and formed parts through complex, multi-stage operations.

Our automation combines robotics and process control to support transfer between forging presses, preheat stations, and post-forming systems.

These forge automation systems increase throughput by reducing transfer time and improving positional accuracy, allowing operators to monitor entire lines from centralized controls. The result? Greater reliability across industrial workflows that depend on repeatability.

How Forging Automation Enhances Efficiency and Throughput

Forge automation increases production volume by limiting inefficiencies that slow down forming cycles.

Ajax/CECO/Erie Press focuses on process stability, ensuring that each piece of forging equipment stays aligned with output expectations.

Our advanced automation technology supports continuous operation, helping facilities reduce wear on components caused by inconsistent movement and unnecessary stops between forming stages.

Streamlining Multi-Step Processes with Robotic Forging Technology

Forging automation simplifies production lines that require multiple forming and handling stages. Robotic forging systems accurately manage hot part movement, especially where human intervention can slow cycle time or introduce errors.

In a typical automated line, the process may look something like this:

- Loading raw billets onto conveyors

- Feeding billets into preheat stations

- Transferring hot parts to the forging die

- Extracting formed parts from the press

- Positioning parts for trimming or final processing

Each step works in sync to prevent slowdowns and improve repeatability.

Industries Benefitting from Forging Automation Technology

This kind of technology supports industries where uptime, part consistency, and production speed are absolutely critical.

Our systems are used by professionals across various sectors, helping manufacturers meet throughput targets and material handling demands with less waste and fewer stoppages.

Some common industrial applications include the following:

- Automotive component manufacturing

- Aerospace structural forging

- Oil and gas equipment production

- Rail and transportation hardware

- Defense-grade metal forming

Regardless of your industry or application, we tailor automation systems to match the specific requirements of each environment.

Our Legacy in Driving Automation Innovation in Forging

Ajax/CECO/Erie Press has led forging automation advancements since automation first entered metal forming.

We developed early integration methods between mechanical systems and programmable controls, pushing forging equipment into automated production long before it became the industry standard.

Our involvement in automation began before digital controls became widespread, and we continue to engineer new solutions for operations looking for precision, speed, and total control across every stage of the forging process.

Forging Automation FAQs

Learn more about our forging automation services through our frequently asked questions.

Can you add new forging automation systems to older equipment?

Yes! We configure forging automation systems to work with both new and legacy equipment. Our team evaluates mechanical interfaces, timing requirements, and control compatibility to integrate robotic handling into existing forging lines without a full replacement.

What safety benefits come with implementing forge automation?

Forge automation reduces manual handling in high-temperature areas and minimizes operator exposure to moving components. By automating part transfer, manufacturers improve safety conditions and lower the risk of injury in forging environments.

Do you offer technical support for installed forging automation systems?

Yes, we provide ongoing technical support, remote diagnostics, and parts access for all installed forging automation systems. Our service team helps maintain uptime and performance long after commissioning.

Ready to improve control and consistency in your metal forming line? Ajax/CECO/Erie Press builds forging automation systems that match your production needs and equipment setup.

Contact our team to discuss your application, get technical guidance, and request a quote for forge automation solutions that fit your workflow.