We Are A Comprehensive Customized Supplier of All Things Forging

More than 40% of Ajax/CECO/Erie Press machines built since 1875 remain in service today. Very few manufacturers of anything in the world can make a statement like that. It’s a reflection not only of the durability and quality or our hardware, but also the longevity of our company itself. So it goes without saying that we take pride in building quality machines that stand the test of time. And we look forward to helping you meet your business priorities now and for years to come.

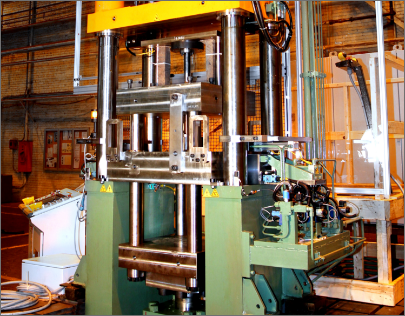

Forging

Forging

No matter what type of forging equipment and tools you’re looking for, Ajax/CECO/Erie Press has what you need. From pneumatic or hydraulic forging presses, forging machines/upsetters and forging hammers and everything in between, we’re your one-stop shop.

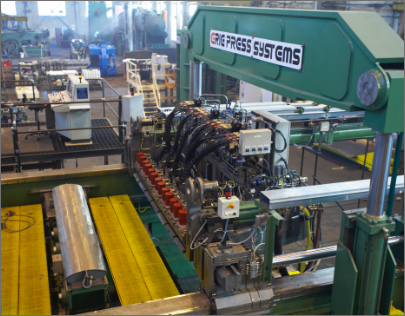

Carbon Extrusion

Carbon Extrusion

Ajax/CECO/Erie Press designs and builds the highest quality carbon extrusion presses in the industry. Superior electrodes and cathodes improve performance and the overall efficiency of all associated melting/smelting processes.

Compression Molding

Compression Molding

Our compression molding presses are ideal for all composite materials. Designed to easily and quickly switch molds, as well as built with rugged construction for less maintenance, a compression molding press from Ajax/CECO/Erie Press will maximize your productivity.

Powder Compacting

Powder Compacting

Components with exceedingly complex geometries can be manufactured quickly with powder compaction processes. Whether your compaction processes call for ceramics, powdered metal, carbon anodes or other materials, we will work with you to design a press to your exact specifications.

SPF/Hot Forming

SPF/Hot Forming

Whether you need a hot forming press or a super plastic forming (SPF) press, Ajax/CECO/Erie Press has the right machines for forming titanium and certain types of aluminum and stainless steel. All of our hot forming and SPF presses implement a multi-zone heating process, which ensures precise thermal control, uniform platen heating and consistent part production.

Stretch Forming

Stretch Forming

Stretch wrap forming methods provide several unique advantages over other types of metal forming. Since stretch forming machines keep the metal under constant tension, they minimize imperfections. They also allow you to perform a task in one step that would otherwise require several machines and multiple steps — improving efficiency and saving you time and money.