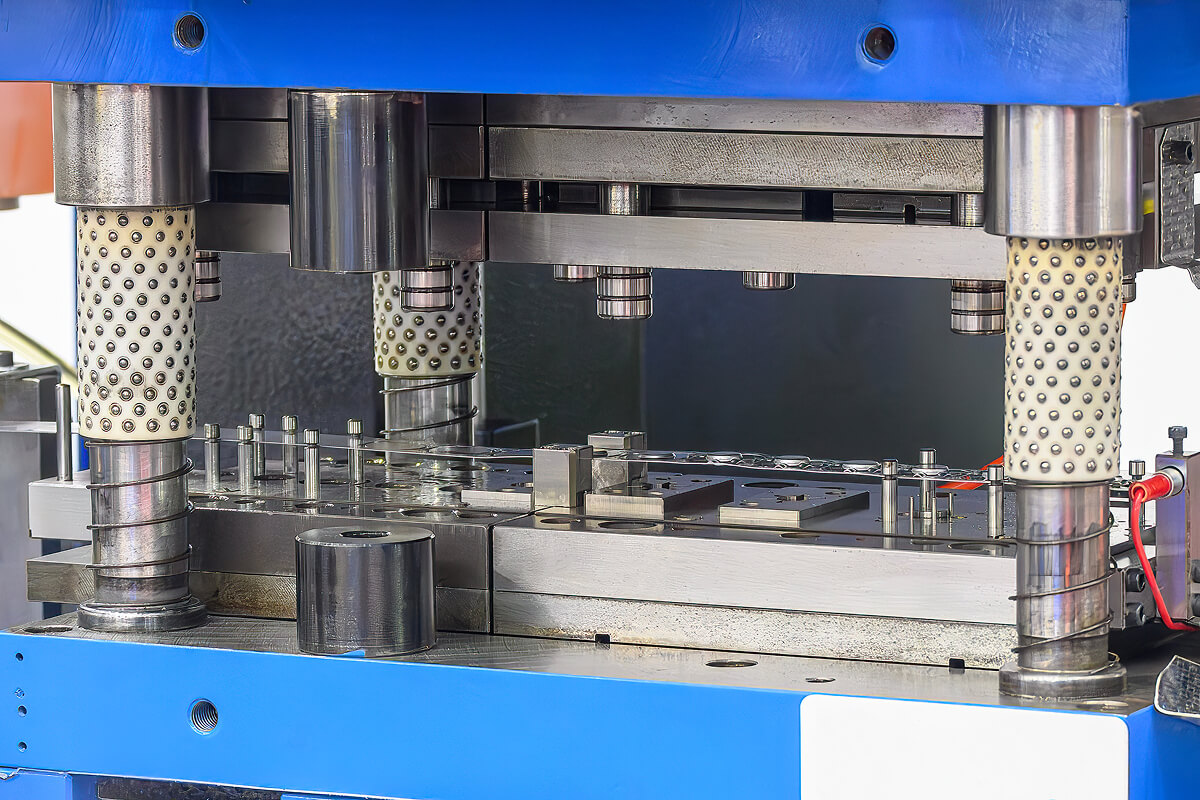

A trim press machine delivers precise flash removal during forging, ensuring cleaner parts and faster post-forging workflow. Ajax/CECO/Erie Press designs heavy-duty trim presses for industrial durability and repeatable performance in challenging environments.

As a trusted trim press manufacturer with over a century of engineering experience, we offer machines that integrate seamlessly into your line and support high-output production day after day.

Why a Trim Press Machine is Critical in Forging Operations

A trim press machine applies consistent, high-force pressure to remove excess flash from forged parts while they’re still hot. This functionality prevents deformation and minimizes the need for secondary machining.

This process improves dimensional accuracy and surface finish, which is crucial for parts that require tight tolerances or additional assembly.

Without a trim press, flash removal becomes inconsistent and labor-intensive, slowing down throughput and increasing the risk of scrap.

These machines also help extend die life by reducing stress during manual trimming or grinding. In modern forging environments, trim presses align with the pace and precision of every production line.

Choosing the Right Trim Press for Your Production Needs

Selecting the right trim press starts with understanding your production volume, material type, and part complexity.

Press tonnage, bed size, and cycle speed all affect how efficiently the machine supports your forging line.

You’ll also need to consider compatibility with upstream and downstream equipment to maintain continuous operation. After all, a poorly matched trim press adds bottlenecks instead of solving them.

Key Features to Look for in Industrial Trim Presses

The right machine will elevate your entire operation. When evaluating trim press machines for sale, look for features that enhance productivity and long-term performance, including the following:

- Precision-guided rams for consistent shearing and clean cuts

- High-tonnage capability to handle tough materials and larger forgings

- Adjustable stroke settings for part variety without manual reconfiguration

- Rigid frame construction to reduce deflection under load

- Quick-change die systems to minimize downtime between production runs

- Automated controls and safety systems for operator efficiency and protection

Choosing a trim press with these capabilities ensures better output, longer tool life, and fewer unplanned stoppages.

Benefits of Partnering With a Trim Press Manufacturer You Can Trust

Ajax/CECO/Erier Press builds machines that outlast trends, budgets, and sometimes entire buildings. We proudly engineer production solutions that are explicitly meant for real-world forging environments.

Our legacy spans over 145 years, and we support every customer with dedicated engineering, service, and replacement part options.

When reliability matters, we deliver machines that don’t just perform, but keep entire operations supported and functional.

Trim Press Machines for Sale with Custom Engineering Options

Our trim press lineup includes fully customized solutions built for specific tonnage, cycle rates, die configurations, and automation integration.

We collaborate with your engineering and operations teams to design equipment that fits your floor plan, workload, and long-term production goals.

Whether you need a unique bed size, specialized tooling, or control system upgrades, we configure every machine to match your exact requirements.

View our Trim Press Brochure for more information.

Trim Press Machine FAQs

Learn more about our trim press machine options through our frequently asked questions below.

How much does a trim press machine cost?

Trim press machine pricing depends on tonnage, automation level, and customization. A standard unit costs less than a fully customized system for complex part removal or high-volume production.

Can a trim press machine be integrated into an existing forging line?

Yes, most modern trim press machines can fit into existing lines without full reconfiguration. We evaluate your current workflow, material flow, and automation requirements to ensure seamless integration.

What kind of maintenance does a trim press require?

Industrial trim presses need regular inspection of hydraulic systems, lubrication points, die alignment, and safety systems. We offer preventative maintenance plans, replacement parts, and service programs to keep your machine running like new.

How do I know which trim press tonnage is right for my parts?

Tonnage requirements depend on your part size, flash thickness, and material hardness. Undersizing leads to poor flash removal and die damage, while oversizing wastes energy and budget.

It’s time to add a trim press machine that truly meets your production demands. Our team will help you choose the right trim press, customize it to your specs, and support you from build to install.

Connect with a leading trim press manufacturer today for expert guidance and a detailed quote tailored to your operation.