Ajax/CECO/Erie Press has been delivering forging machinery since 1875, and we incorporate our years of experience into every project we undertake. We maintain ISO 9001 certification for quality management, and our equipment operates in leading industrial forging plants worldwide.

Forge Machinery Built for Long-Lasting Strength

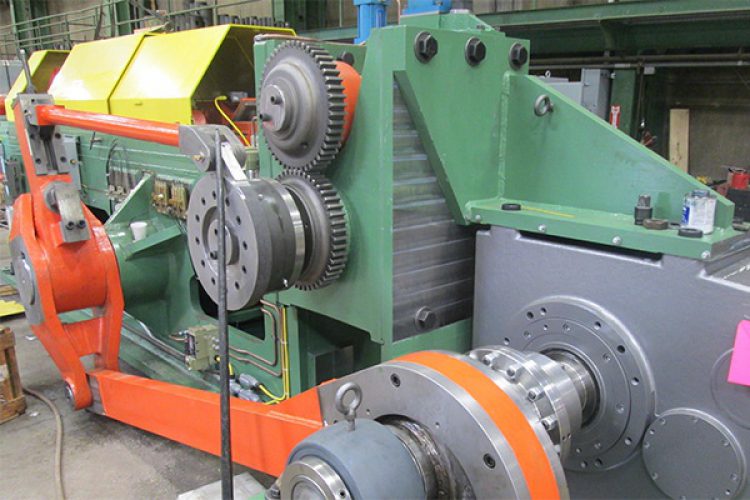

Professionals continue to trust our forging machines because they use heavy-duty weldments and high-capacity components that maintain alignment under continuous load.

Forging hammers and presses include integrated systems for shock resistance and energy absorption to reduce wear and extend service life.

We use premium-grade materials and exacting build standards to ensure each forging machine withstands high force, temperature, and production demands over time.

Custom Forging Solutions

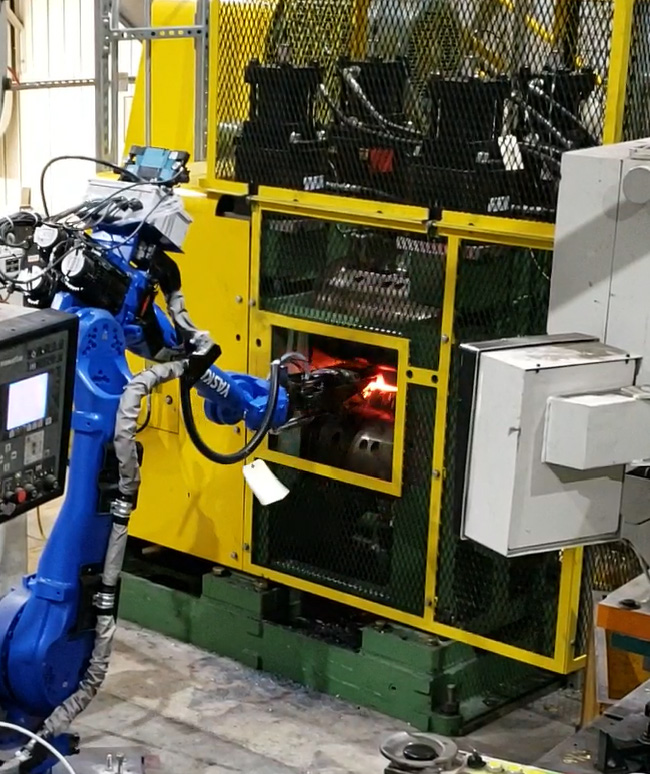

Ajax is proud to offer engineered-to-order forge machinery that fits your production layout and part specifications. Our expert team configures press stroke, ram speed, bed size, and control systems to meet specific process goals.

We also support integration with automation systems and existing infrastructure to ensure easy implementation across all of our partners’ operations.

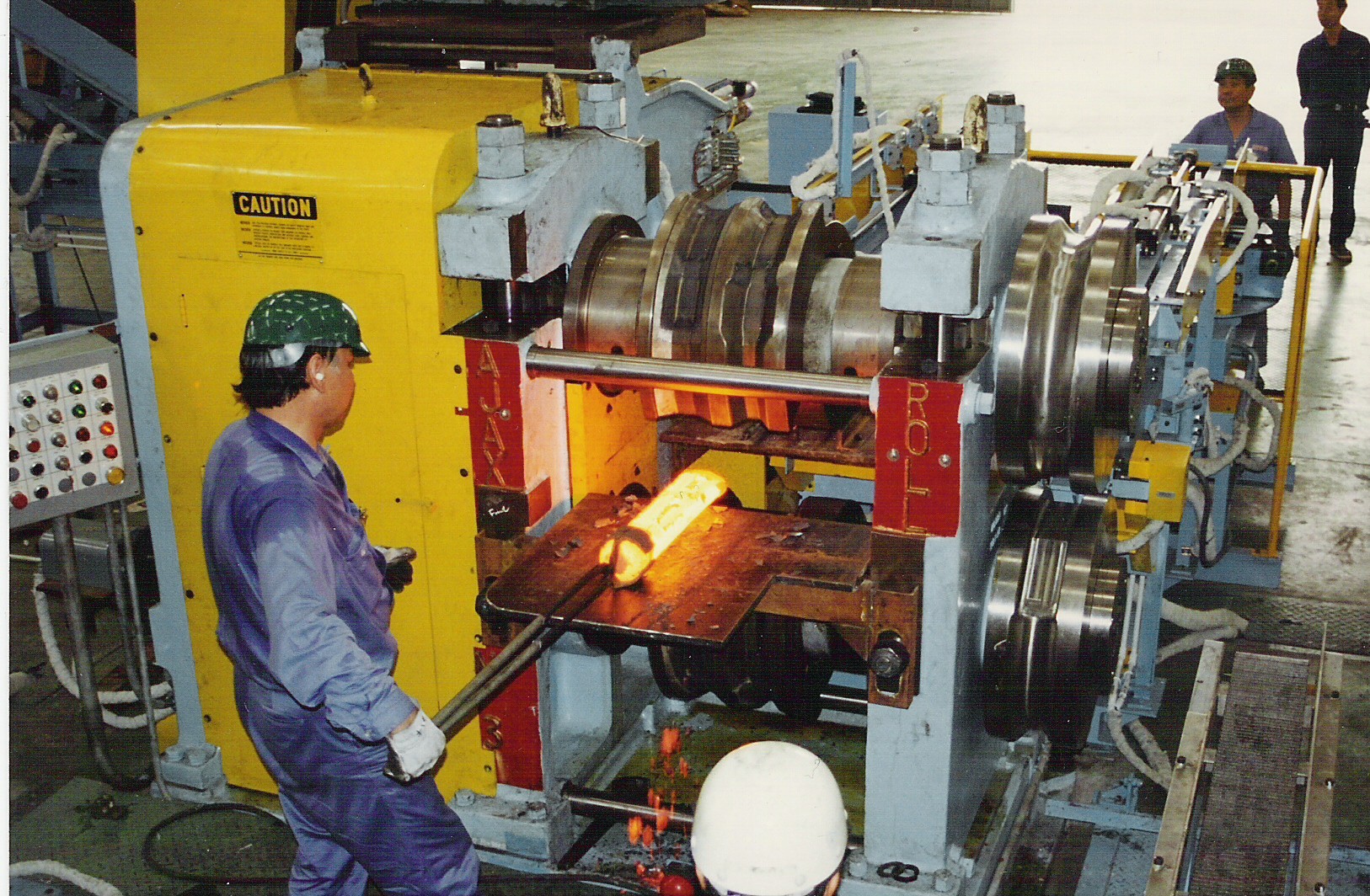

Decades of Expertise in Forging Machine Manufacturing

With a legacy that spans generations of industrial advancement, Ajax brings unmatched expertise to every forging machine we produce. Our team combines historical knowledge with modern engineering to solve complex metal-forming challenges.

We continue to support legacy machines and develop next-generation forging equipment with the same commitment to quality and precision that has defined our work since the beginning.