Ajax/CECO/Erie Press has the widest range of In-line Wire Drawers; Bar Drawers; Drawing, Straightening & Cut-off Machines; In-line Drawing & Cut-off Machines; and Instacut Machines in the forging industry.

With our state-of-the-art construction and engineering processes, advanced systems, proven components and sophisticated automation, Ajax/CECO/Erie Press Wire and Bar Drawers allow our customers to produce the highest quality forged components — fast and at scale.

Wire Drawers

Used with cold-forming equipment, Ajax/CECO/Erie Press Wire Drawing Machines draw and coat hot-rolled, pickled, and limed- or phosphate-coated rod as the rod feeds into the heading. The cold-drawn stock produced not only exceeds commercially available stock in accuracy, but also possesses numerous other desirable properties, such as straightness, clean coating and no age hardness.

- With suitable mechanical provisions, Ajax/CECO/Erie Press Straight Liner Wire Drawers will operate with any make of cold-heading machine

- Built in nine sizes, they can handle all rod diameters from number 0 to number 8

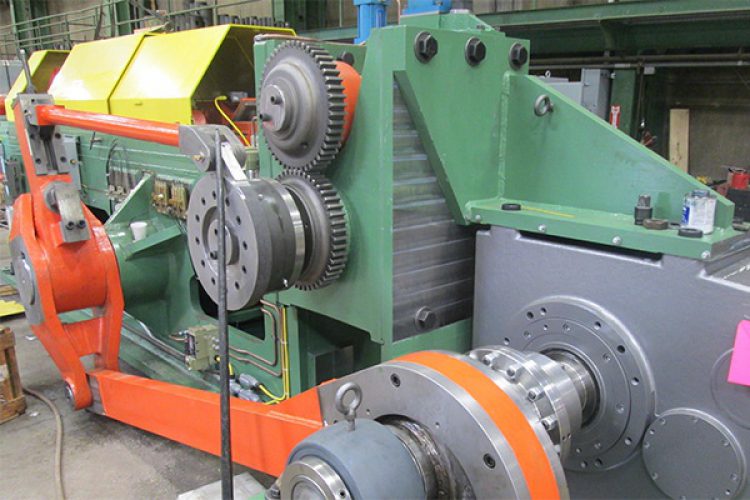

Bar Drawers

Ajax/CECO/Erie Press Bar Drawers are designed for sizing of hot rolled bars to accurate cold-drawn dimensions in hex, round or other shapes. Current capacities are up to 2” in diameter.

Draw / Straighten / Cutoffs

- Ajax/CECO/Erie Press Drawing, Straightening & Cut-off Machines are designed to produce cut-to-length blanks or straight bars from hot-rolled steel coils. They manufacture blanks and bar stock for diameters ½” to 1-1/2”.

- Ajax/CECO/Erie Press Instacut Machines produce volume-controlled slugs if less than one-to-one ratio (length to diameter). They can be coupled with standard Ajax/CECO/Erie Press Wire Drawers for conversion from hot rolled coiled (rod) stock to slugs.

- Ajax/CECO/Erie Press In-line Drawing and Cut-off Machines draw hot-rolled, coiled stock for producing smaller diameter blanks (1/4” to 5/8”).

Preferred Supplier of Wire and Bar Drawers

Manufacturing customers all over the world rely on Ajax/CECO/Erie Press for customized wire and bar drawing solutions. We take the time to understand your unique situation, so we can provide a thorough, professional consultation and strategic assessment. Because we work with you from concept to implementation, you can be assured your custom forging equipment will meet your needs exactly.