In the aerospace manufacturing industry, Ajax/CECO/Erie Press equipment plays a large role. The equipment is utilized in a variety of fashions to bend, bond, form, and straighten metal into components like airframes, fuselages, and spars.

As the largest forging equipment supplier in North America, providing service to the world, with over a century of experience in the forging industry, Ajax/CECO/Erie Press is the preferred supplier to many industries–including the aerospace industry.

Essential Forging Equipment for Aerospace Manufacturing

Manufacturers in the aerospace industry must adhere to specifications under process-specific pressure and temperature applications. Their aerospace forging equipment must typically be customized to meet these requirements that demand precise controls and processes to reliably achieve the specified final product. Therefore, they are looking for a partner with profound expertise in metal forming—like Ajax/CECO/Erie Press, which is essential for their success.

“A custom-engineered forging machine and control solution is often required when precise control of position, axis synchronization, force, and heat is essential for the forging\forming process,” says Bill Goodwin, Vice President of Sales— Ajax/CECO/Erie Press.

Erie Press Systems, which merged with Ajax CECO in 2019 under parent company ParkOhio, is no stranger to the aerospace industry. For decades the company has been manufacturing custom-engineered hydraulic presses for aerospace applications, including:

- Metal forming

- Stretch forming

- Composite presses

- Compression molding presses

- Cold extrusion

- Roll forging

- Forging presses

Erie Systems that have been essential in the aerospace industry include:

- Contour roll forming

- Extrusion stretch forming

- Hot stretch straighteners

- Isothermal forging

- Powder compaction presses

- Sheet stretch forming

- Superplastic forming – diffusion bonding hot presses

Isothermal Forging

Isothermal forging is a hot working process that attempts to maintain the workpiece at its maximum elevated temperature throughout the entire forging operation. These are typically high-tonnage machines that must have the capability to move at a wide speed range, including very slow velocities down to 0.5mm per minute to generate a precise strain rate curve required to form these parts

Sheet Stretch Forming

Stretch forming machines for sheets are designed to meet all tonnage, length, and width specifications. These machines have been widely used in stretch forming aluminum fuselage, wing, and engine cowl panels. Still, the process has now evolved to forming exterior panels on a high-speed locomotives, recreational vehicles, and buses, as well as proprietary aerospace and commercial rocket applications.

Additionally, a special adaptation of high-tonnage stretch-forming machines can manufacture the main structural support spar used on large commercial aircraft. Heavy cross-section beam material is gripped in specially designed jaws, stretched to its yield point, and bent over a die that follows the plane’s curvature.

Extrusion Stretch Forming

Extrusion stretch-forming machines bend and form complex aluminum, titanium, and stainless-steel structural components within the aircraft industry. These metals have proven challenges with other manufacturing processes. The extrusion stretch forming process produces extremely accurate and repeatable part production.

“Typically, aluminum tends to wrinkle if bent. However, the stretch forming process can eliminate those defects, because the first step is stretching the part to yield, and then bending it so that you can bend extrusions without wrinkling,” says Bill Goodwin.

Superplastic Forming – Diffusion Bonding Hot Presses

Diffusion bonding takes two thin sheets of material and bonds them together into one homogeneous piece via a long heat and pressure cycle. The bonded metal components being joined undergo only microscopic deformation. The process is utilized in aerospace.

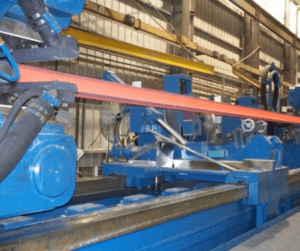

Hot Stretch Straighteners

This forming machine press is utilized to resistively heat, stretch, and straighten long extruded tubes, or flat plates, because the cooling process after the heated extrusion cycle tends to introduce curvature. The pressure is gradually reduced when using the hot stretch straightener as the long, extruded metal component cools. This maintains a tensile load on the part, maintaining part straightness during the cooling process.

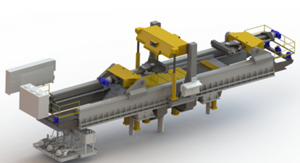

Contour Roll Forming

Contour roll-forming machines offer another type of bending process that goes beyond stretch forming. Specifically designed to apply curvature to aircraft stringers and frames, contour roll-forming machines can operate on three planes of space instead of two. Contour roll forming also requires less force and offers the advantage of theoretically unlimited length as the materials need only pass through the rollers.

The Future of Forging in the Aerospace Industry

“In the next 5-10 years, instead of hydraulic drives, we expect electric presses driven by geared servo motors and larger roller screws to become increasingly important to aerospace manufacturers for any application that is sensitive to oil leaks or where precise control is required,” concludes Goodwin. “So, we are developing the technology today.”

For additional information on our capabilities in the aerospace industry contact us.