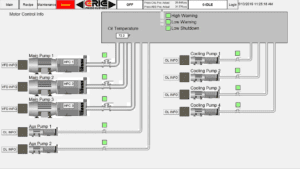

Graphic Human Machine Interface (HMI) capability allows operators to see how a forging press is functioning and speeds local/remote diagnostics and troubleshooting.

Although today’s forging industry is the result of more than a century of process developments, forging presses are delivering better results thanks to the capabilities of HMIs to improve production uptime and process control. A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, in particular to a forging system. HMIs are software applications that graphically present information to operators about the state of various processes in a format that looks like the actual machine or display panel. The information can be accessed locally (at the machine) or remotely (within the plant or at an offsite location) via PC, laptop, or smartphone.

For forging, next-level HMIs are aiding operators not only to see how equipment is functioning but also to anticipate how it should be performing. This is accomplished with dynamic animated models and schematics, live trending, and diagrams.

Del Williams, a technical writer illustrates how HMI is assisting the forging industry in technical advancement, increased profitability, and advanced competitive advantages.

To learn more about ACE’s HMI capabilities contact our experienced technical sales team.