Within aerospace manufacturing, a wide variety of heavy-duty, metal-forming, hydraulic presses with capacities of 10,000 tons or more are required to bend, form, bond, or straighten aluminum, titanium, and alloys into structures and components such as fuselages, spars, and airframes.

Technical writer, Del Williams examines aerospace metal forming to provide an expert survey of the key equipment and processes, in the Aerospace Manufacturing Magazine article.

Within aerospace manufacturing, a wide variety of heavy-duty, metal-forming, hydraulic presses with capacities of 10,000 tons or more are required to bend, form, bond, or straighten aluminum, titanium, and alloys into structures and components such as fuselages, spars, and airframes.

On the production floor, specialized machines such as stretch forming presses, hot stretch straighteners, contour rolls, superplastic forming presses, diffusion bonding presses, and powdered metal compaction presses are often required to manufacture to custom aerospace specifications under process-specific applications of pressure and temperature.

Because these machines are customized and require precise controls and processes to reliably achieve the specified final product, partnering with a manufacturer with deep expertise in such metal forming is frequently essential for success.

Find out how Ajax Ceco Erie Press has been supporting the Aerospace industry for decades with our customized equipment:

- Stretch forming machines

- Sheet stretch forming

- Extrusion stretch forming

- High production rate stretch forming

- Hot stretch straighteners

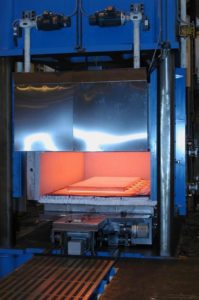

- Super plastic forming – diffusion bonding hot presses

- Isothermal forging

- Powder compaction presses

For more information on how we can support the aerospace industry contact us today.