Human Machine Interface (HMI) technology enables operators to visualize how a forging press is operating and improves real-time remote support such as troubleshooting and training.

While the modern-day forging process is over a century old—forging presses are no stranger to process and technological development. HMI capabilities have changed the way manufacturing works by improving production uptime and process control.

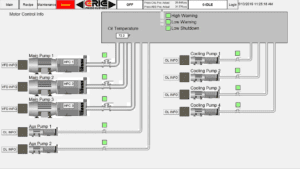

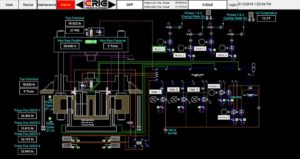

At Ajax/Ceco/Erie Press we utilize HMI as a dashboard that connects a person to a machine—a forging system. Our HMI software provides the operator with graphically illustrated information regarding the state of the machine and various processes, that looks like the actual machine or control panel. The information that is generated can be accessed remotely to improve communication for training and troubleshooting of the forging tools.

“Cutting-edge HMIs are visual learning tools for forging operators to observe the normal machine operation, to expedite troubleshooting when something goes wrong,” said Bill Goodwin, Vice President of Sales – ACE.

For forging, HMIs are assisting operators to not only view how the machine is currently operating but it also provides an opportunity to anticipate how the machine should be performing. This is possible with dynamic animated models and schematics, live trending and diagrams. This type of information will improve the wide variety of forged products.

“Even less experienced personnel can look at a well-designed HMI screen, watch the press run, and then learn how it functions. Operations can monitor live press positional and force data as the machine transitions through the production cycle. When something is out of sequence or stops abruptly mid-cycle, they can quickly troubleshoot because the HMI provides a graphical window into the machine control system and its processes, identifying problem areas,” Goodwin added.

Traditionally, throughout the long history of forging, manufacturers with forging equipment have had to rely on experienced operators utilizing manual processes to review the components’ condition. With massive press equipment applying many tons of force to workspaces for critical industries—minimizing downtime and unexpected repairs is essential.

Therefore, inspections of forging equipment were typically performed during scheduled shutdowns, or during a repair only. Due to the limited time for observation, from the skilled workers, the inspection was not comprehensive. If a defect was overlooked at the time of a maintenance review, it would not be apparent until the press or production line broke down—causing unplanned downtime.

“With manual gauges, if a pump started to fail, the operator might not notice until the machine was unable to complete a cycle,” Goodwin said.

With the rising constraint of hiring a skilled workforce a manual inspection is almost impossible to complete during normal operations. As it would be challenging for a veteran press operator to progressively diagnose issues without modern technology.

“At times, a forging machine would stop, and no one knew what was wrong with it, why it stopped, or where the error occurred,” said Goodwin.

There are many types of HMI, with the different types of forging the simplest form of this technology is visual terminals where information can be entered and data viewed, with no historical data stored. With more advanced HMI technology press operators have the capabilities to monitor how the machine is operating with ample information to troubleshoot and ensure that the equipment’s downtime is minimal. The advanced technology also enables the operator to search different components and historical data to make the most informed decisions.

At Ajax/Ceco/Erie Press, we start the HMI with a digital solid work model of the press, then we import that into HMI software. From there we are able to break the machine apart and dynamically animate it to display critical operational statistics. Then the press operator has a high-level view of the equipment they can even monitor main ram tonnage, main cylinder pressure, moving platen position, last cycle time, and current cycle time.

This information allows the operator to understand the press’s internal operation more effectively by observing the information as it is displayed through the HMI technology. This in turn will provide them with the background information necessary to quickly diagnose any issues while the press is in operation.

While this information can be displayed at the manufacturing operations, it can also be viewed remotely via a mobile device. This will provide the ability for online diagnostics directly from the OEM engineers—providing them with a platform to view the machine’s health without having the time and monetary expense to travel to the machine’s location. With customers ranging past the span of North America it could be an expensive and time-consuming process to get an OEM engineer onsite of the machine. This will eliminate the downtime of the press with the quick turnaround response direct from the OEM.

“The goal is to avoid production downtime by preventing problems as well as reducing the time to find, diagnose, and solve them. Remote diagnostics allow us to monitor the forging equipment to resolve any potential issues promptly. For example, we can remotely reset a switch that didn’t activate or fine-tune the target position of the precise speed of the press ram,” said Goodwin.

The HMI systems we are utilizing enables review of historical data and real-time, searchable technical documents and schematics as well as animated schematics. This allows the operators to quickly zero in on specific data from a high level. We can use this technology on any of our equipment from forging hammers, hot forging equipment to hydraulic presses.

“With historical data, if a component is starting to fail, maintenance often can identify and replace it before catastrophic failure,” said Goodwin. “Instead of spending days trying to locate the right technical documentation and reading through data sheets or wiring schematics that can be 100 pages long, the data is searchable and immediately available to operators.”

A forging press can operate for nearly a century; however, it is essential for the proper process and technological updates for the forging equipment to be efficient. The HMI capabilities significantly increase production, virtually eliminate downtime and improve profitability.

To learn more about ACE’s HMI capabilities contact our experienced technical sales team.