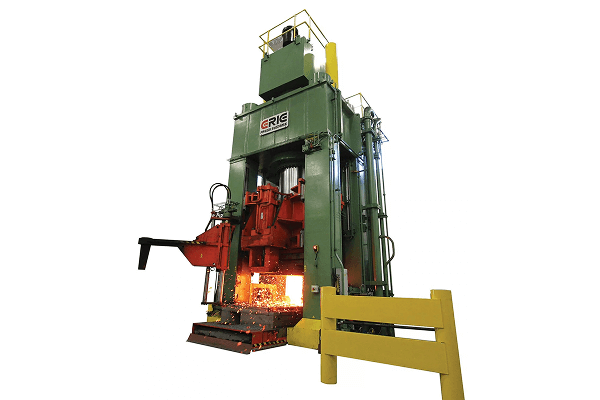

Looking to boost production, cut downtime, and get more consistency out of every press cycle? A hydraulic forging press from Ajax/CECO/Erie Press is the upgrade your operation needs. Built for power and precision, these machines are workhorses, whether you’re shaping heavy alloys or fine-tuning complex parts. We design each one to help you hit your goals faster, with less waste and fewer headaches.

What Our Hydraulic Forge Press Can Do for You

A hydraulic forge press is an investment in production speed, consistency, and reliability. It should make your work smoother and easier. That’s why we build ours to handle real-world demands on the shop floor, with the strength to move serious material and the smarts to adapt to your workflow.

Here’s what our hydraulic forging presses are built to deliver:

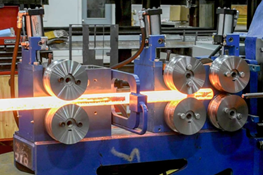

- Precise control for warm, cold, and preforming operations

- Smooth extrusion of complex parts with high repeatability

- Power ranges from 250 to 15,000 tons to match your production goals

- Faster stroking speeds to shorten cycle times

- Quick die changes to reduce downtime between runs

- Variable speed settings to fine-tune each job

- Versatility across metals, plastics, ceramics, and more

- Tough, long-lasting builds that keep maintenance low and uptime high

We’ll design a custom hydraulic press that’s made to solve your exact challenge.

A Legacy of Know-How, Built Into Every Press

When you’ve been designing forging equipment for over a century, you learn what keeps production floors running and customers coming back. At Ajax/CECO/Erie Press, we combine generations of experience with forward-thinking engineering to deliver hydraulic forging presses that perform day in and day out. Whether you need a standard machine or a fully custom hydraulic press, we’re here to make sure it’s the right fit for your operation and that it stays that way.

But we’re more than just builders; we’re partners in your success. From the moment we kick off your project, you’ll be working with a dedicated project manager who keeps communication clear and consistent. You’ll always know where things stand, and you’ll have the flexibility to make changes as needed.

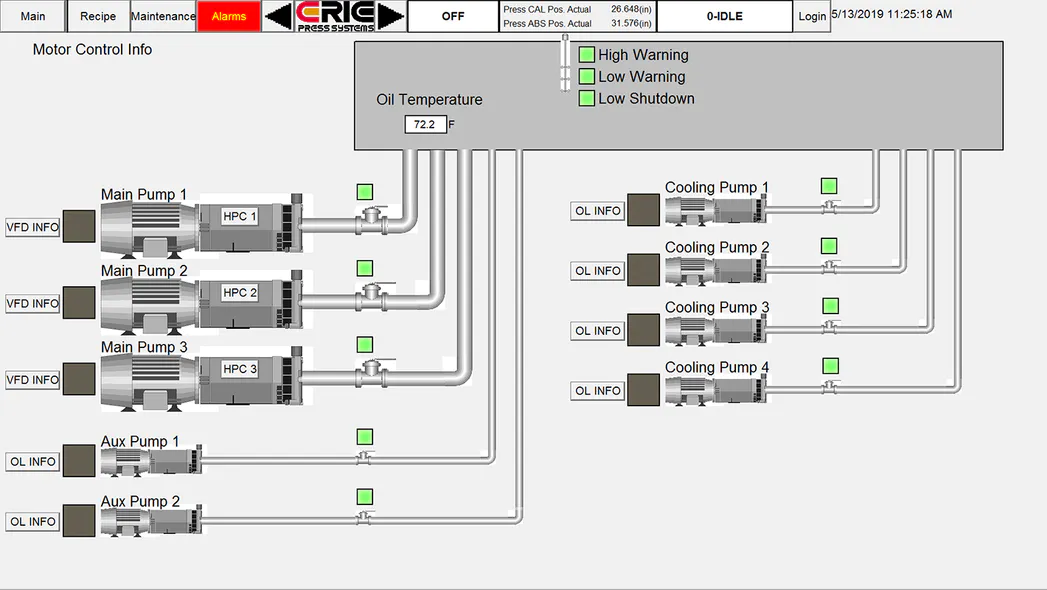

We take the time to understand your team, your workflow, and your production goals because that’s how we design the right press for your business. And once it’s up and running, our job isn’t done. We offer hands-on training for your operators, detailed work instructions, and assistance in developing a preventive maintenance program. Our parts stocking and remote support options minimize downtime and maximize uptime because we know that every minute your press is offline costs you money.

At Ajax/CECO/Erie Press, service isn’t an afterthought. It’s built into everything we do.

Frequently Asked Questions About Our Hydraulic Forge Press

We talk to forging professionals every day, and a lot of the same questions come up. Here are a few things folks often want to know before they invest in a hydraulic forging press. For even more info, check out our Custom Forging Solutions Catalog.

What size hydraulic press do I need?

That depends on what you’re forging. We build presses from 250 to 15,000 tons, so whether you’re doing light work or serious heavy lifting, we’ll help you find the right fit.

Can I get a custom hydraulic press for my application?

Absolutely. In fact, most of our clients do. We’ll work with you to engineer a custom hydraulic press that matches your materials, cycle time, and throughput goals with no guessing required.

Do you have a hydraulic forge press for sale right now?

Yes, we offer both standard models and fully custom builds. If you’re looking for a hydraulic forging press for sale immediately, we’re happy to walk you through current availability and options.

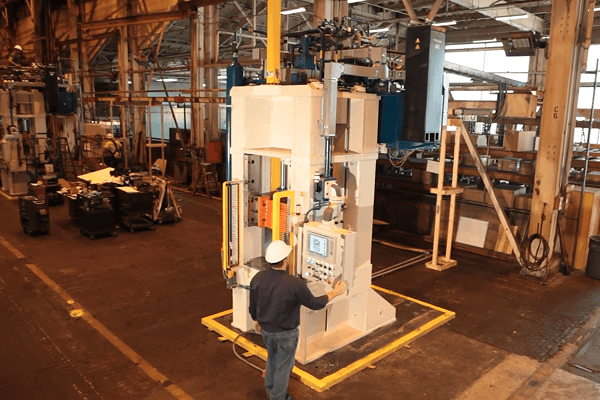

Closed Die Hydraulic Press Rebuild

Ajax/CECO/Erie Press specializes in repairing, servicing, and providing parts for existing machines while leveraging our expertise to manufacture modern equipment for the aerospace, automotive, rail, medical, and military industries in forging, forming, and extrusion.

Who Uses Our Hydraulic Forging Press?

If you’re in aerospace, automotive, energy, or defense, chances are you already know the value of a well-built hydraulic forge press. These machines are essential for producing high-strength, high-precision parts at scale, from turbine blades to drive shafts and everything in between. Our presses are on shop floors around the world, powering operations that can’t afford to cut corners or lose time.

Reliable and built to last, an Ajax/CECO/Erie Press hydraulic forging press can help cut your maintenance costs, keep production running smoothly and maximize your ROI. Let’s get you set up with the best machine for your operation!