Customer: A custom engineering forge manufacturer in North America.

Industry: Agriculture, construction, energy, material handling, military and defense, and transportation

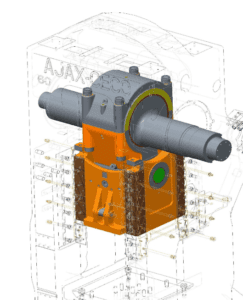

Application: Over 15 Ajax and Erie Mechanical Presses, including:

- (15) 1,000 T – 6,000 T Ajax Mechanical Press

- (2)2,500 T – 4,000 T ERIE Mechanical Presses

Problem: The customer’s Pinion shaft failed on one of their mechanical presses. This critical component had a lead time of 20 weeks. The equipment would not properly operate without the Pinion shaft—resulting in a 20-week loss of production.

Solution: The customer utilized the Ajax/CECO/Erie Press stocking program to stock semi-finished parts. We were able to obtain the final dimensions of the component and finish machining in 3 weeks. This saved the customer at least 17 weeks of downtime.

Additionally, due to inflation and demand the pricing for the required parts had more than doubled since they had secured the semi-finished part—resulting in a lower cost to the customer.

Ajax/CECO/Erie Press Advantage: The advantage of Ajax/CECO/Erie Press’ Industry Leading Stocking Program is that customers who enroll will have the opportunity to avoid long lead times for critical components. This will minimize their unplanned downtime and allow them to get their equipment back online faster.

To help save our customers time and reduce costs, we manufacture parts for the Stocking Program to a semi-finished state—so they may be interchangeable for several machines depending on the machine design—and then finish them to precise specifications when needed.

Working with the OEM of the machine is an enormous benefit to the customer in that the OEM has the original engineered design specifications for their equipment’s components which considers material hardness/softness and clearances to mating components, not just to ensure initial functionality but to make sure it is not just a temporary fix that will cause an ultimate catastrophic failure at some point in the remaining the life of the equipment.