U.S.-based forging and forming equipment suppliers can optimize processes, uptime, and cost for the long haul with responsive expertise and readily available parts and service.

Purchasing new forging equipment from a “low-cost” overseas supplier that offers a limited number of standard options from a catalog can be costly in the long run. In addition, in the notoriously high-impact forging industry, standard one-size-fits-all equipment often will not fit the application without some level of customization. It inevitably will require spare parts and service that can be difficult to find years later.

When production depends on the reliable operation of forging equipment, the problem can be even more severe. If overseas catalog equipment (such as forging frames, presses, or hammers) breaks down or fails due to part shortages, production bottlenecks, or logistical delays, then late delivery of parts to customers can occur. Subpar forging equipment can also become obsolete and must be prematurely retired or replaced if it is purpose-built for one specific project and cannot be adapted to meet future market demands.

As a result, many manufacturers in North America are turning to domestic OEMs that can adapt and customize forging equipment instead of purchasing from inflexible overseas catalog suppliers. When needed, such firms have necessary parts and services readily available for customers utilizing well-established, quality brands. However, manufacturers should consider some key issues to future-proof an investment in new forging equipment.

If overseas catalog equipment does not meet the requirements of the process, extra steps and labor may be necessary, and manufacturing certain parts may not be feasible. For example, if a 1000-ton press is purchased and 1200 tons are required, the equipment may not be able to make the part.

Issues can also occur if the press bed or daylight is too small and unable to accommodate a new tool set. Alternatively, if the forging process dictates that a machine must change velocities multiple times within an inch, a catalog purchase may only be capable of one forging speed.

Some manufacturers may select forging equipment for a specific project without thinking long-term about the availability of spare parts for service years or what will happen when the current project is completed and new parts need to be made.

High-Quality Forging Equipment

Any manufacturer purchasing forging equipment today must consider if spare parts and service support will be available over the next 10-20 years. Of course, high-quality forging equipment can operate much longer—up to 80 years in some cases, but longevity must be considered.

The ability to adapt the equipment to meet future demand is also important. Manufacturers should give themselves some flexibility to cover the unknowns, including how the equipment can be modified to make other parts in the future.

Overseas Limitations

Forging and forming equipment suppliers from China or India may provide standard machines, but they are often unwilling or unable to modify their standard offerings. As a result, the quality of the forging equipment’s control components can be a concern as is the use of component parts that are essentially “knockoffs” of U.S. brands.

Although European forging equipment is more on par with domestic offerings in terms of quality, replacement parts still must be sourced from there. Long lead times for replacement parts, limited phone support (due to time-zone differences), on-site customer-support response time, shipping times, and customs delays can result in extended production time.

Domestic Advantage

The ability to expedite service and repair for various equipment types commonly found on North American manufacturing floors was just one of the considerations behind merging leading brands Ajax Manufacturing, Chambersburg (CECO), and Erie Press Systems under the parent company ParkOhio.

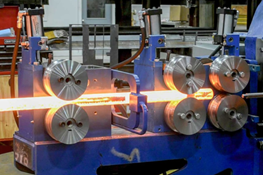

The U.S.-based company Ajax/CECO/Erie Press, a manufacturer of forging equipment since 1875, is not the largest OEM forging equipment supplier in North America. This includes horizontal and vertical forging presses, mechanical and hammer forging presses, and hydraulic presses for various applications. However, the merger means manufacturers that have utilized one or more brands over the past 100 years now have a single-source OEM for equipment, parts, and service.

Founded in 1895, Erie Press Systems offers custom hydraulic presses for numerous applications, including forging (closed-die, open-die, and ring performing), metal forming, and carbon extrusion. The company also offers composite presses, stretch-forming machines, legacy hammers, and standard mechanical forge presses.

“With the companies combining, we have additional resources to share, so we can respond to support requests faster and have more field-service technicians available. In addition, our investment in R&D and new technology has also improved due to the merger,” said Bill Goodwin, Vice President of Sales at Ajax/CECO/Erie Press.

When replacement parts are required, Goodwin says Ajax/CECO/Erie Press offers stocking programs for long lead-time items—such as main gears, eccentric shafts, rams, etc. –that most customers do not stock due to the cost. This type of program holds the part in inventory for the customer. The customer pays a percentage of the cost and then the balance when they take possession of the part, even years later.

“A customer stocking program with minimal upfront investment can eliminate months of downtime due to long-lead-time parts,” Goodwin said. “Instead, multiple machines with parts of similar size and design can have the parts manufactured to a semi-finished state in preparation for use with any of the machines. Then, when needed, the exact dimensions for the down machine can be provided so the part can be completed to specification, ready to install.”

Information such as the design specifications (including critical data on high-wear parts), the material grade of the steel, the heat-treating process used, and the required clearances used in the engineering of a particular piece of equipment are usually all needed for a quality repair – and certainly for a rebuild.

The same design expertise gives decades of longevity to the forging equipment service life. Some of the company’s equipment has successfully performed for nearly a century with refurbishment and necessary updates.

“If a manufacturer needs a part for a century-old Hammer, for example, the company probably has the prints for it, so we can supply replacement parts or provide a good substitute. That is just not possible from the overseas options that were not even in business 10 years ago,” Goodwin said.

Lastly, domestic OEMs allow forgers to take advantage of the most advanced automation and diagnostic options currently available. For example, entire forging-line “cells” can be created that include sophisticated communications that report production rate and machine performance back to company networks.

Ajax/CECO/Erie Press has also developed an online diagnostic system for remote monitoring and support through a remote Ethernet diagnostic connection on all Erie Press machines. The Ethernet-bases control system provides engineers a platform to remotely view the machine’s health as it operates.

Conclusion

Based solely on the lowest initial investment, some forgers may be tempted to purchase forging equipment from overseas catalog suppliers. Conversely, the forgers who go forward with reshoring efforts and select a domestic partner that can customize forging equipment to their specific requirements and rapidly respond with any needed parts and service may gain significant, long-term advantages that save them money in the long run.

To learn more about Ajax/CECO/Erie Press’s capabilities and the advantages of working with a domestic supplier, contact our experienced technical sales team.