Ajax/CECO/Erie Press proudly manufactures industrial forging presses for high-output and long-term performance. Backed by more than a century of experience, we’ve crafted each forging press to meet demanding production requirements across various industries.

Clients choose Ajax/CECO/Erie Press time and time again because we don’t cut corners. Every forging press we craft is supported by rigorous quality control standards and American manufacturing expertise. Our team works with industry professionals to deliver machines that meet tonnage requirements, minimize downtime, and ensure reliability across production cycles.

Trim Presses

Trim Presses

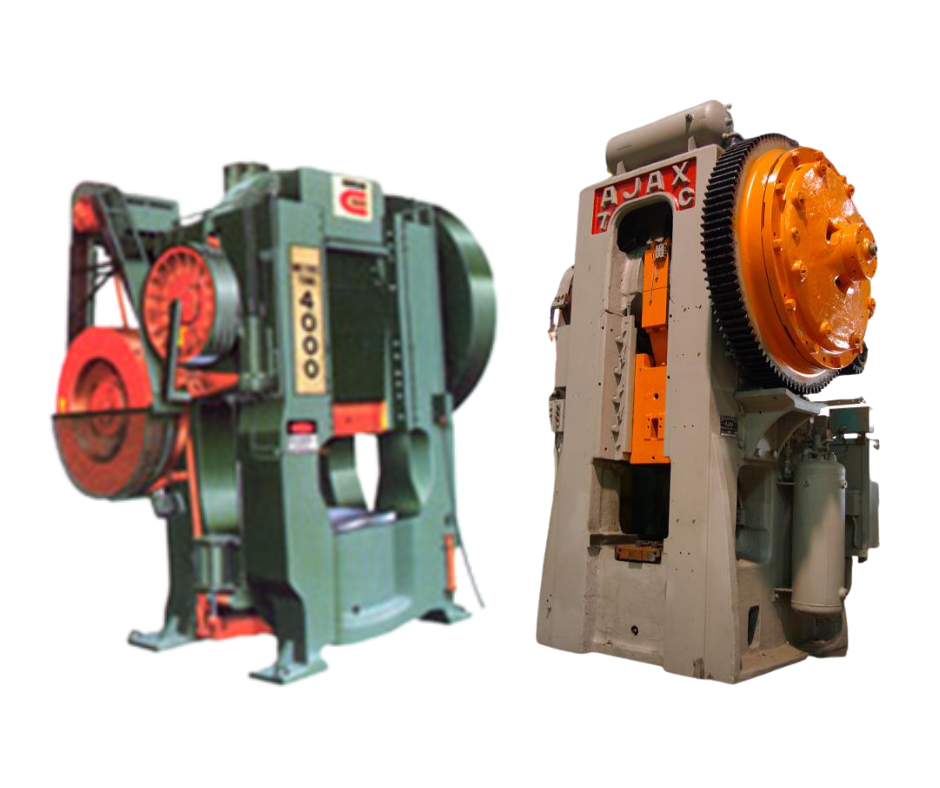

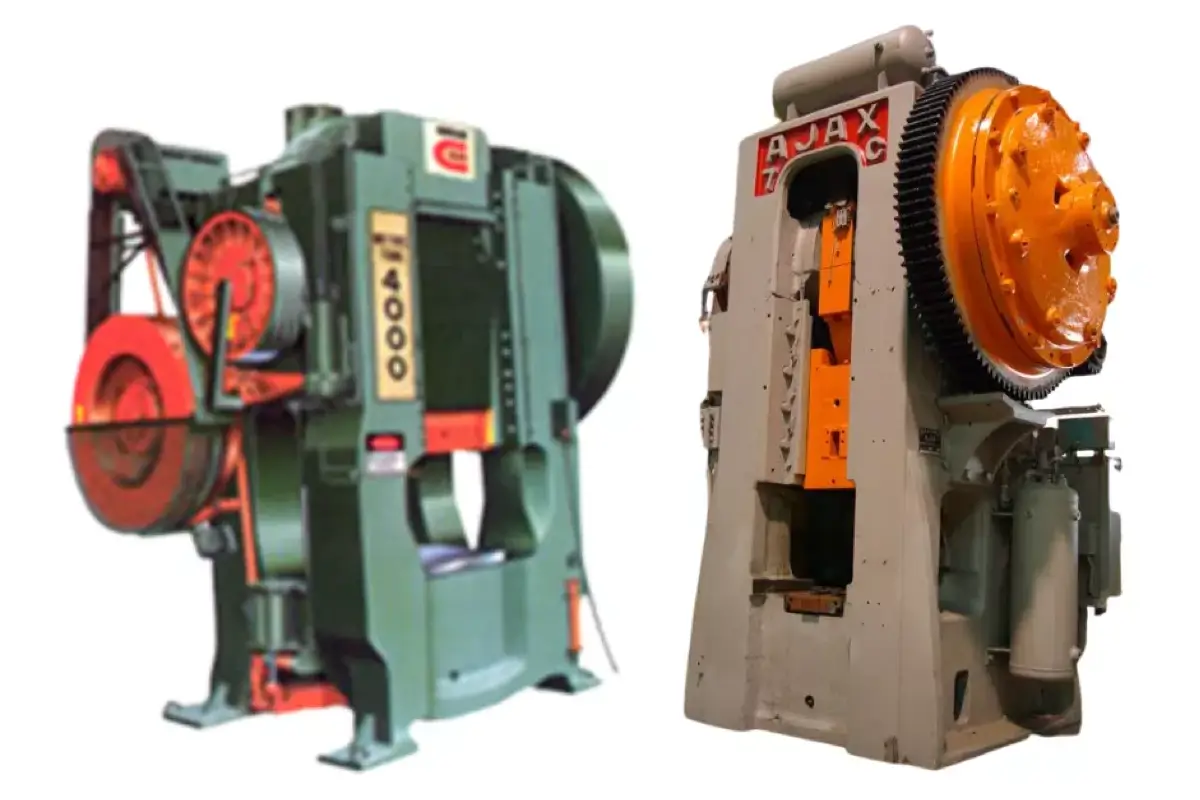

Mechanical Forging Presses

Mechanical Forging Presses

Hydraulic Forging Presses

Hydraulic Forging Presses

Closed Die Forging Presses

Closed Die Forging Presses

Open Die Forging Presses

Open Die Forging Presses

Ring PreForming Presses

Ring PreForming Presses

High-Performance Forging Press for Sale

Ajax/CECO/Erie Press sells industrial forging presses built to meet production demands across high-load, high-volume environments.

Our inventory includes mechanical and hydraulic forging press machines built for speed, force, and consistent production. Professionals utilize these machines in complex forging environments where output consistency and press durability are essential.

We also offer both new and remanufactured options built to meet exacting standards for industrial forging. Whether you’re hoping to expand capacity or replace an outdated system, ACE forging presses are ready to support production with the efficiency and longevity that today’s operations demand.

Choosing the Right Forging Press for Your Operation

Forging presses are designed specifically for your operations. This means that you must take the time to determine components like your operational goals and long-term service needs in order to make the right investment.

Key Factors That Influence Forging Press Machine Selection

Choosing the right forging press machine comes down to more than just price and tonnage. (However, those factors are important, too.)

You must take the time to consider the following components when finding your perfect forging press for sale:

- Stroke length and shut height suitable for the required die setups

- Cycle speed that meets production volume without overloading the system

- Floor space and foundation needs that align with your facility layout

- Energy consumption and controls that support cost-effective operation

Considering these elements means you reaffirm that the press delivers consistent performance without causing bottlenecks, excess wear, or compatibility issues on the production floor.

Mechanical vs. Hydraulic Forging Presses

Both mechanical and hydraulic forging presses offer distinct benefits in the forming process. Understanding the operational differences between the two can help determine which system is best suited for your specific needs.

The most significant differences between mechanical and hydraulic forging press machines include the following:

- Mechanical presses deliver faster cycle rates, making them ideal for high-volume jobs with consistent part specs.

- Hydraulic presses offer greater stroke control and force application flexibility, better suited for complex or varied geometries.

- Hydraulic systems provide higher force at lower speeds, which is helpful in precision or multi-directional forming.

- Mechanical drives often have lower long-term energy consumption in continuous, repetitive applications.

Why an ACE Forging Press Is a Smart Long-Term Investment

Ajax/CECO/Erie Press builds each of our forging presses with longevity in mind, offering durable construction, high-strength components, and proven engineering that holds up over years of industrial use.

Every forge press for sale is supported by a team with extensive knowledge of forging processes and equipment life cycles. Ajax/CECO/Erie Press provides ongoing service, remanufacturing options, and upgrade paths that help operations adapt without replacing entire systems.

When you’re seeking upgrades to reduce downtime, manage long-term costs, and keep your production lines going, an ACE forging press offers a return on investment that extends well beyond installation.

FAQs About Press Forging

Below, we’ve answered some of your most frequently asked questions regarding press forging.

What industries use forging press machines?

Various industries utilize forging presses, including aerospace, automotive, oil and gas, defense, energy, and heavy industrial manufacturing, where high-strength metal components are necessary.

How much tonnage do I need for my application?

Tonnage requirements depend on material type, part geometry, and the forming process. Ajax/CECO/Erie Press can help evaluate specs to ensure accurate forge selection.

What’s the lead time on a press forging?

Press forging lead time varies based on machine size and configuration. Custom orders and remanufactured units typically range from several months to over a year.

Request a Quote and Enhance Your Operation’s Craftsmanship Today

If you’re ready to invest in a forging press or want more details about our available machines or services, contact Ajax/CECO/Erie Press today. Our team can answer questions, provide quotes, and help you identify the right equipment for your operation.

Use the form below or reach out directly to start the conversation about a forging press for sale.