Stocking Program Saving Customers On Lost Production Time

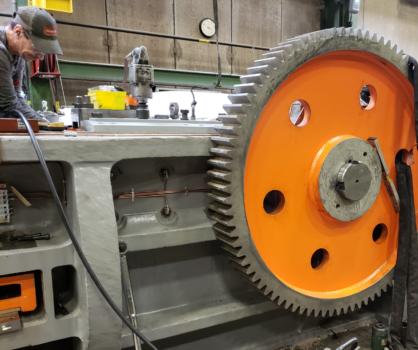

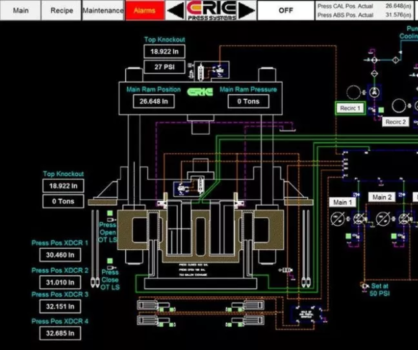

Customer: A custom engineering metal forming manufacturer supporting global forming technologies for automotive, commercial, and industrial markets. Industry: Automotive Application: 10 Ajax Mechanical Presses 1300T -4,000 T Ajax Mechanical Presses Problem: The customer’s Drive Plate failed on one of their mechanical presses. This critical component had a lead time of 18 -20 weeks for a new manufacture. The downtime from the press resulted in...